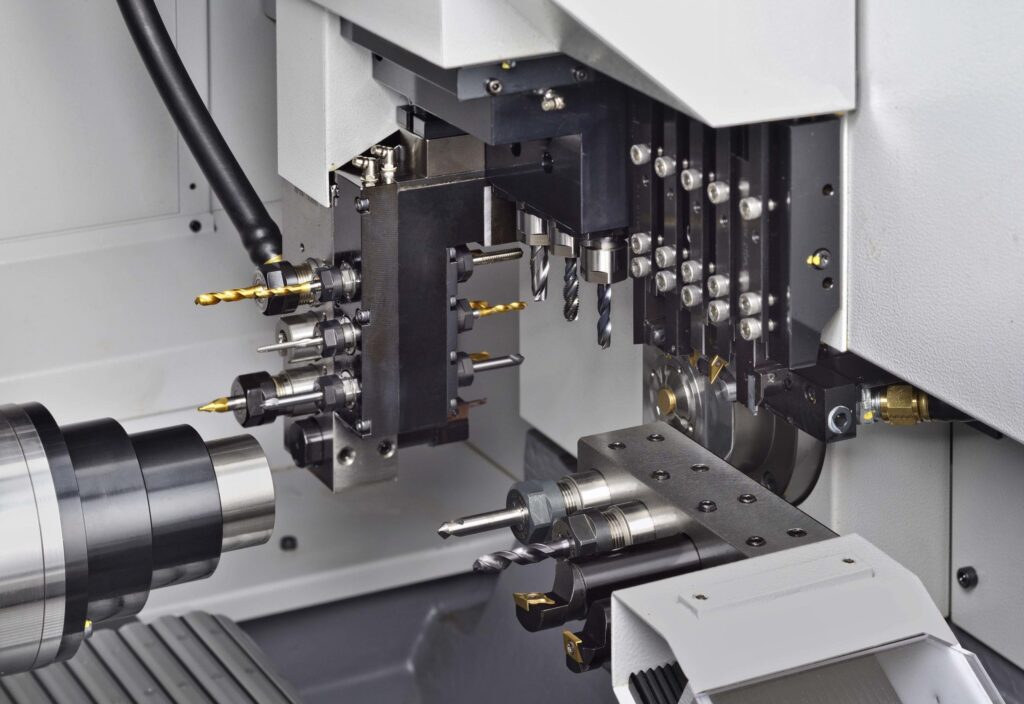

CNC Machining (Lathe & Mill)

CNC Machining: Precision Machining Services:

Advantech Precision Machining (APM) is your reliable partner for precision machining services that help you create complex components and parts with optimal accuracy and efficiency. We offer a wide range of custom manufacturing solutions using advanced machinery and equipment to ensure consistent precision and optimal performance.

Our machines and technologies are driven by our expert team of engineers and technicians, who bring a wealth of experience to every precision CNC machining project, making sure your specifications are matched to perfection.

With ultra-tight tolerances and the ability to produce reliable and repeatable results, APM is the best choice for precision machining custom modules and components for a comprehensive manufacturing experience. That’s because we understand the importance of precision machining services in our client’s manufacturing processes, and we strive to exceed their expectations by delivering high-quality products and services on time and within budget. Reach out to us to see how we can help you achieve your machining needs

CNC Machining: Manufacturing And Design Guidelines

CNC machining is a manufacturing process that is carried out through computer-controlled CNC machine tools. In CNC machining, computer programs control the movement and operation of machine tools through pre programmed instructions to achieve precise machining of parts. This article will provide you with some manufacturing and design guidelines for CNC machining.

Manufacturing Guidelines

Part Design

Before conducting CNC machining, it is necessary to first design the parts. Designers should consider the capabilities and limitations of CNC machine tools and design part geometries that meet processing requirements.

Material Selection

Choosing materials suitable for CNC machining is very important. Some common CNC machining materials include metal alloys, plastics, wood, etc. Select appropriate materials according to the requirements of the parts to ensure machining quality and performance.

Manufacturing Process Planning

It is necessary to develop a detailed process plan before conducting CNC machining. The plan should include processing sequence, cutting parameters, clamping methods, etc., to ensure that the parts can be processed as expected.

Writing Machining Programs

The machining program is the core of CNC machining. By writing machining programs, the geometric information of the parts is transformed into instructions that the machine tool can understand, in order to control the movement and operation of the machine tool.

Process Control

During CNC machining, process monitoring and control are required. By real-time monitoring of parameters during the machining process, such as cutting force, cutting temperature, etc., machining parameters can be adjusted in a timely manner to improve machining quality and efficiency.

Design Guidelines

Design Geometric Shapes

When designing CNC machining parts, geometric shapes should be simplified as much as possible to avoid complex curves and sharp inner and outer corners. This will help improve machining accuracy and reduce processing time and costs.

Consider Processing Sequence

When designing CNC machining parts, the rationality of the machining sequence should be considered. Try to break down the processing process into simple steps to avoid increasing processing difficulty and cost due to unreasonable processing sequence.

Avoid excessive cutting: When designing CNC machining parts, excessive cutting should be avoided as much as possible. Excessive cutting can lead to material waste and increased processing time. Reasonably select cutting tools and parameters to minimize cutting volume.

Consider Clamping Methods

When designing CNC machining parts, the rationality and feasibility of clamping methods should be considered. Choose appropriate fixtures and fixture positions to ensure the stability and accuracy of the parts during the machining process.

Consider Process Requirements

When designing CNC machining parts, the rationality and feasibility of process requirements should be considered. Such as surface smoothness, dimensional tolerances, etc. Communicate fully with manufacturers and operators to ensure that the design meets the actual processing requirements.

The manufacturing and design guidelines for CNC machining include aspects such as part design, material selection, manufacturing process planning, machining program writing, and machining process control. Reasonable manufacturing and design guidelines can improve the efficiency and quality of CNC machining, ensuring that parts can be processed as expected.

CNC (Computer Numerical Control) machining can be used to process soft metal materials. Soft metals typically refer to metals with lower hardness and higher plasticity, such as aluminum, brass, and copper. Here are some important precautions for handling soft metals in CNC machining:

Choose suitable cutting tools: For soft metal materials, high-speed drills, blades, and milling cutters are usually used. These cutting tools are capable of working at higher speeds and effectively cutting and cutting soft metals.

Control cutting parameters: In the processing of soft metals, it is necessary to adjust cutting parameters based on the specific material’s hardness and plasticity. These parameters include cutting speed, feed rate, and cutting depth. Appropriate cutting parameters can ensure the efficiency and quality of machining.

Using appropriate coolant: As soft metals are prone to high temperatures during processing, it is important to use appropriate coolant. Cooling fluid can lower the temperature of the machining area, reduce the risk of tool wear and material deformation, and improve the quality of the machining surface.

Maintaining stable clamping: Soft metals are often relatively soft during processing, so appropriate fixtures and clamping methods are needed to ensure the stability of the workpiece. This helps to avoid vibration and deformation during the machining process.

Proper post-treatment: Soft metals usually require appropriate post-treatment, such as deburring, polishing, and coating. These post-processing steps can improve the surface smoothness and overall quality of the final product.

CNC machining of soft metals requires the selection of appropriate cutting tools, adjustment of cutting parameters, use of coolant, stable clamping, and appropriate post-processing. These steps help to obtain high-quality and accurate machining results.

CNC MILLING

Computer numerical control (CNC) is the computerized control of machining tools such as drills, bits, and lathes. CNC machines reductively process a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following programmed instructions.

A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and then executed. The program can be written by a person or, far more often this century, generated by graphical computer-aided design (CAD) software. In the case of 3D Printers, the part to be printed is “sliced”, before the instructions (or the program) is generated. 3D printers also use G-Code.

CNC is a vast improvement over non-computerized machining that must be manually controlled (e.g., using devices such as hand wheels or levers) or mechanically controlled by pre-fabricated pattern guides (cams). In modern CNC systems, the design of a mechanical part and its manufacturing program is highly automated. The part’s mechanical dimensions are defined using CAD software, and then translated into manufacturing directives by computer-aided manufacturing (CAM) software. The resulting directives are transformed (by “post processor” software) into the specific commands necessary for a particular machine to produce the component, and then are loaded into the CNC machine.

Since any particular component might require the use of a number of different tools – drills, saws, etc. – modern machines often combine multiple tools into a single “cell”. In other installations, a number of different machines are used with an external controller and human or robotic operators that move the component from machine to machine. In either case, the series of steps needed to produce any part is highly automated and produces a part that closely matches the original CAD.

At Advantech Precision Machining (APM), we use CNC machining equipment daily to both prototype and for production. We would be happy to give you a tour of our facility. Contact us for more information or for a quote on your next project.

CMM

A coordinate measuring machine (CMM) is a device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe. Various types of probes are used in CMMs, including mechanical, optical, laser, and white light. Depending on the machine, the probe position may be manually controlled by an operator or it may be computer controlled. CMMs typically specify a probe’s position in terms of its displacement from a reference position in a three-dimensional Cartesian coordinate system (i.e., with XYZ axes). In addition to moving the probe along the X, Y, and Z axes, many machines also allow the probe angle to be controlled to allow measurement of surfaces that would otherwise be unreachable.

At APM, we use CMM daily to ensure all of our products are within specification. We would be happy to give you a tour of our facility. Contact us for more information or for a quote on your next project.

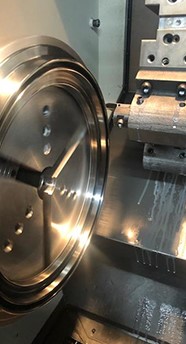

Precision CNC Turning/Lathe

We are proud to bring you high-quality precision CNC turning services. New equipment and advanced technologies guarantee your success. Each component produced in our factory is guaranteed to fit perfectly your requirements. Consistency, tight tolerance and accuracy: this is what our CNC turning machines offer. Our range of machines allows for efficient production and versatility. Whether you need to perform some research and development work, create a few prototypes, or produce only a few components, we can do it. Top-Notch precision turning equipment is at your disposal for all your industrial needs and you will enjoy fast delivery and quality results that equal or exceed your expectations. We work for several industries among which aerospace, robotics, semiconductors and much more. Precision is our job and our passion.

Our team has accumulated years and years of experience operating all sorts of machines and still follow the latest trends in precision CNC machining. Whenever you need precision machine parts, you can call us and simply transfer your requirements over to us, we take care of the rest. At APM, we use CNC lathes daily to both prototype and for production. We would be happy to give you a tour of our facility. Contact us for more information or for a quote on your next project.

Program Management

A single point of contact to keep your parts and assemblies on schedule.

At Advantech Precision Machining (APM), our customers are supported with dedicated program management. With a single point of contact, project details are communicated clearly, your parts & assemblies arrive on time and you always know who to call.

APM’s Program Managers have a comprehensive understanding of our manufacturing facility and will do what it takes to make your project successful.

Our program managers:

- Work to Identify customer goals and needs

- Act as a liaise between the customer, manufacturing floor, engineering, & sales

- Provide ongoing business planning, forecasting and inventory management.

- Coordinate activities between outside contractors

- Provide logistical support ensuring accuracy with documentation, contracts, and delivery.

Our program managers will optimize the manufacturing process for your parts utilizing our state-of-the-art machinery and resources in tandem with your goals as a customer.